Ever wondered what makes your car's engine tick? It's more than just fuel and spark; it's a precisely choreographed dance between different components. One misstep, and your engine could be running rough, losing power, or even facing serious damage. It all comes down to timing – engine timing, that is.

Ignoring the intricate workings under the hood can lead to frustrating performance issues. Poor fuel economy, a lack of power when you need it most, and that unsettling feeling that something just isn't right. These problems can drain your wallet at the gas pump and leave you stranded on the side of the road.

This post is your guide to understanding engine timing: what it is, why it's crucial, and how it all works. We'll break down the complexities into easy-to-understand concepts, empowering you with the knowledge to keep your engine running smoothly and efficiently.

We will delve into the core of engine timing, exploring its importance, the mechanics involved, and common misconceptions. We'll uncover historical facts, address troubleshooting tips, and explain how crucial engine timing is for performance and longevity. You'll learn about timing belts, timing chains, and the role of various sensors in ensuring everything is perfectly synchronized, resulting in peak efficiency and a smoother ride. Ultimately, you'll gain a comprehensive understanding of this critical engine function, enhancing your car knowledge and potentially saving you money on future repairs.

My First Brush with Engine Timing: A Lesson Learned

I'll never forget the first time I really understood the importance of engine timing. It was back in my college days, and I had a beat-up old pickup truck that was my pride and joy. I thought I knew everything about cars, having watched countless hours of car shows. One day, I decided to replace the timing belt myself to save some money. It seemed straightforward enough in the manual.

Armed with my trusty toolbox and a You Tube video, I dove in. Everything went smoothly until it came time to put the new belt on. I got it installed, but I wasn't entirely sure if I had aligned the timing marks correctly. I figured, "close enough," and buttoned everything back up. I started the engine, and it sounded like a bag of bolts being shaken violently. It ran incredibly rough and had almost no power. My "close enough" approach had completely thrown off the engine timing. Panic set in. I had made a huge mistake and probably caused some serious damage.

I had to swallow my pride and tow the truck to a mechanic. He explained in detail how even a slight misalignment of the timing belt could cause such dramatic problems. The valves weren't opening and closing at the right time, resulting in poor combustion and the awful noise I heard. I learned my lesson the hard way: precision is key when it comes to engine timing. This experience fueled my desire to truly understand how engine timing works and why it's so critical. Understanding engine timing is the backbone of engine health, directly impacting performance, fuel efficiency, and longevity. A properly timed engine ensures the intake valves open at precisely the right moment to draw in air and fuel, that the spark plugs ignite the mixture at the peak of compression, and the exhaust valves open to release burnt gases efficiently. When timing is off, these processes are disrupted, leading to reduced power, poor fuel economy, increased emissions, and potential engine damage. Modern engines employ sophisticated electronic systems to manage timing, adjusting it dynamically based on load, speed, and other parameters to maximize performance and efficiency. By optimizing the combustion process, engine timing helps minimize wear and tear, extending the life of critical components such as pistons, valves, and connecting rods.

What Exactly is Engine Timing?

Engine timing refers to the precise coordination of various engine components, primarily the crankshaft, camshaft, and valves. These components must work in perfect synchronicity to ensure the engine's cylinders fire at the correct moments, allowing for efficient combustion and optimal performance. The crankshaft is the engine's backbone, converting the reciprocating motion of the pistons into rotational power. The camshaft controls the opening and closing of the intake and exhaust valves, regulating the flow of air and fuel into the cylinders and the expulsion of exhaust gases. The timing belt or chain connects the crankshaft and camshaft, ensuring they rotate in sync. A properly timed engine guarantees that the intake valves open at the exact moment to draw in the air-fuel mixture, the spark plugs ignite the mixture at the peak of compression, and the exhaust valves open to release the burnt gases efficiently.

When the timing is off, these processes are disrupted, leading to a range of problems. Advanced timing, where the spark plugs fire slightly earlier, can boost power but may also cause knocking if the engine is not designed for it. Retarded timing, where the spark plugs fire slightly later, reduces the risk of knocking but can lead to lower power and increased fuel consumption. Modern engines use sophisticated electronic control units (ECUs) and sensors to continuously adjust timing based on various factors, such as engine speed, load, and temperature, to optimize performance and fuel efficiency. Understanding engine timing is crucial for diagnosing and resolving a wide range of engine issues, from poor performance to unusual noises and increased emissions. Proper timing ensures that the engine runs smoothly, efficiently, and reliably, maximizing its lifespan and minimizing the need for costly repairs.

A Glimpse into the History and Myths of Engine Timing

The concept of engine timing has evolved significantly since the early days of internal combustion engines. Early engines relied on very basic mechanical systems, and timing adjustments were often crude and imprecise. Over time, advancements in metallurgy, manufacturing, and control systems have led to the sophisticated timing mechanisms found in modern engines. Early timing systems often used simple gears to connect the crankshaft and camshaft. These systems were reliable but offered limited adjustability. As engine designs became more complex, timing belts and chains were introduced to provide greater flexibility and precision. Timing belts, made of reinforced rubber, offered quieter operation but required regular replacement to prevent catastrophic failure. Timing chains, made of metal, were more durable but could stretch over time, affecting timing accuracy.

One common myth is that you can significantly improve engine performance by drastically altering the timing. While minor adjustments can optimize performance in certain situations, extreme changes can lead to severe engine damage. Another myth is that timing belts never need replacement if they look fine. In reality, timing belts degrade over time due to heat, oil, and wear, and should be replaced according to the manufacturer's recommended schedule, regardless of their appearance. With the advent of electronic engine management systems, timing control became much more precise and dynamic. Modern ECUs use sensors to monitor various engine parameters and adjust timing in real-time, optimizing performance, fuel efficiency, and emissions. Variable valve timing (VVT) systems, introduced in the late 20th century, further revolutionized engine timing by allowing the camshaft timing to be adjusted on the fly, providing improved torque and horsepower across a wider range of engine speeds. As engine technology continues to advance, timing systems are becoming even more sophisticated, incorporating features like cylinder deactivation and advanced combustion strategies to further improve efficiency and reduce emissions.

The Hidden Secrets of Engine Timing

One of the hidden secrets of engine timing lies in understanding how seemingly small adjustments can have a significant impact on engine performance. For example, slightly advancing the timing can improve throttle response and increase peak horsepower, but it can also increase the risk of engine knocking, especially if the engine is not designed for it. Retarding the timing can reduce the risk of knocking and improve low-end torque, but it may also decrease overall power and fuel efficiency. The key is to find the optimal balance for your specific engine and driving conditions.

Another hidden secret is the importance of proper maintenance. Regular inspection of the timing belt or chain, as well as the associated components like tensioners and idler pulleys, can help prevent unexpected failures and costly repairs. Ignoring these maintenance tasks can lead to catastrophic engine damage if the timing belt or chain breaks. Modern engine management systems also have hidden capabilities. The ECU can often compensate for minor timing inaccuracies, but it can only do so much. Over time, wear and tear on engine components can lead to more significant timing deviations, which the ECU may not be able to fully correct. This is why it's essential to have your engine professionally diagnosed if you suspect a timing issue. Furthermore, understanding the relationship between timing and other engine parameters, such as air-fuel ratio and ignition timing, is crucial for optimizing engine performance. By fine-tuning these parameters together, you can achieve significant gains in power, fuel efficiency, and overall engine responsiveness. Exploring the hidden secrets of engine timing can empower you to better understand and maintain your engine, ensuring it runs smoothly and efficiently for years to come. Whether you're a seasoned mechanic or a casual car enthusiast, delving into these details can unlock a new level of appreciation for the intricate workings of the internal combustion engine.

Recommendations for Maintaining Proper Engine Timing

Maintaining proper engine timing is crucial for the longevity and performance of your vehicle. Start with following the manufacturer's recommended maintenance schedule for your specific make and model. This schedule will outline when to inspect and replace critical timing components like the timing belt or chain, tensioners, and idler pulleys. Regular inspections can catch potential issues before they escalate into major problems, saving you time and money in the long run.

When it comes to replacing timing belts or chains, always use high-quality parts from reputable brands. Cheaper aftermarket parts may not meet the stringent specifications required for proper engine timing, leading to premature wear and potential engine damage. Consider having the water pump replaced at the same time as the timing belt, especially if the water pump is driven by the timing belt. This can save you labor costs in the future, as the water pump is often located behind the timing belt. If you notice any symptoms of a timing issue, such as a rough-running engine, reduced power, poor fuel economy, or unusual noises, don't delay in getting your vehicle professionally diagnosed. Early detection and repair can prevent more serious and costly damage. Finally, consider investing in a quality timing light or scan tool if you plan to perform timing adjustments yourself. These tools can help you accurately set the timing and ensure that your engine is running at its optimal performance level. Understanding the intricacies of engine timing empowers you to take proactive steps to maintain your vehicle's health and performance. By following these recommendations, you can ensure that your engine runs smoothly, efficiently, and reliably for years to come.

Understanding Timing Marks and Their Significance

Timing marks are crucial indicators for aligning the engine's crankshaft and camshaft during timing adjustments or replacements. These marks ensure that the valves open and close in perfect synchronization with the piston's movement, optimizing combustion and overall engine performance. Typically, timing marks are found on the crankshaft pulley or harmonic balancer and on the camshaft sprocket or gear. These marks align with fixed points on the engine block or cylinder head when the engine is at top dead center (TDC) on the compression stroke of the first cylinder.

Accurate alignment of these marks is essential for proper engine operation. If the timing marks are misaligned, even by a small degree, it can lead to a variety of issues, including reduced power, poor fuel economy, increased emissions, and potential engine damage. When replacing a timing belt or chain, it's critical to ensure that the timing marks are properly aligned before tensioning the belt or chain. Using a timing light or scan tool can help verify the accuracy of the timing after the belt or chain is installed. Some engines may have multiple timing marks or require special tools for accurate alignment. Consult the vehicle's service manual for specific instructions and torque specifications. Ignoring timing marks or attempting to guess the alignment can result in serious engine damage and costly repairs. Understanding the significance of timing marks and taking the time to align them properly is essential for anyone working on engine timing. Whether you're a seasoned mechanic or a DIY enthusiast, paying attention to these details can ensure that your engine runs smoothly and efficiently for years to come.

Essential Tips for Diagnosing Engine Timing Issues

Diagnosing engine timing issues requires a systematic approach and a good understanding of engine mechanics. Start by listening carefully to your engine. Unusual noises, such as knocking, pinging, or backfiring, can indicate a timing problem. A rough-running engine, especially at idle, can also be a sign of misaligned timing. Reduced power and poor fuel economy are other common symptoms of timing issues. If you notice any of these symptoms, it's important to investigate further.

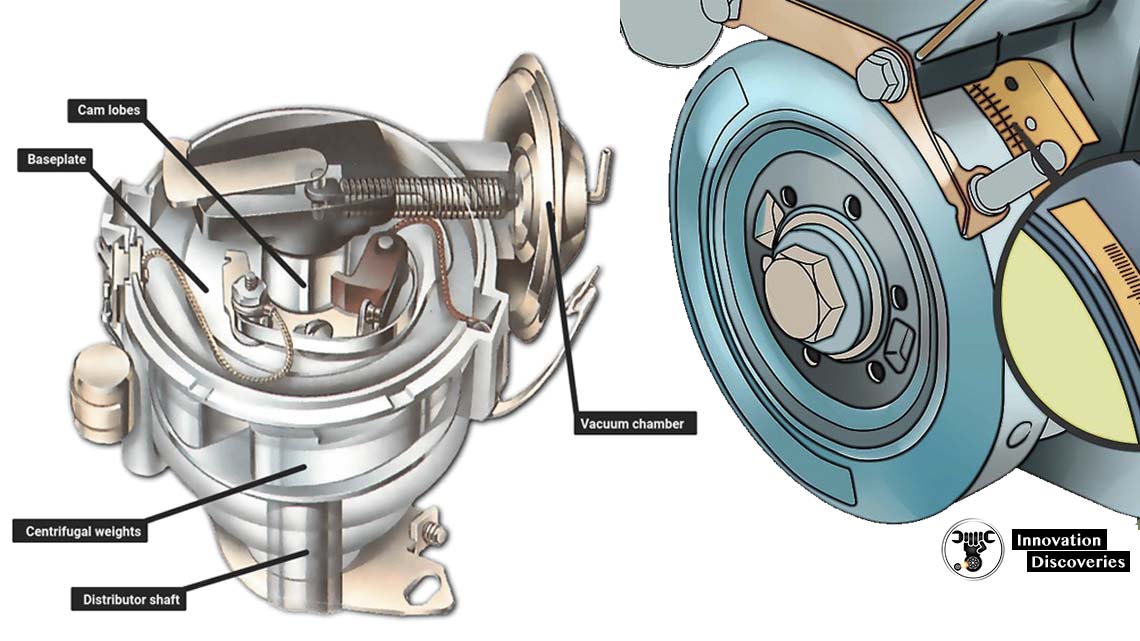

Begin by checking the timing belt or chain for wear, cracks, or damage. If the belt or chain is worn or damaged, it should be replaced immediately. Inspect the tensioner and idler pulleys for proper operation. A loose or worn tensioner can cause the timing belt or chain to slip, leading to timing issues. Use a timing light to verify the accuracy of the ignition timing. The timing light will allow you to see the timing marks on the crankshaft pulley while the engine is running, ensuring that the timing is within the manufacturer's specifications. If the timing is off, you may need to adjust the distributor or reprogram the ECU. If you suspect a more complex timing issue, consider using a scan tool to check for trouble codes. The scan tool can provide valuable information about the engine's operating parameters and any potential problems. Finally, don't hesitate to seek professional help if you're unsure about diagnosing or repairing a timing issue. A qualified mechanic can accurately diagnose the problem and perform the necessary repairs to get your engine running smoothly again. Following these tips can help you effectively diagnose engine timing issues and take the necessary steps to keep your vehicle running at its best. Proper diagnosis and repair of timing issues can prevent more serious engine damage and ensure optimal performance and fuel economy.

Common Tools Needed for Engine Timing Work

Working on engine timing often requires specialized tools to ensure accuracy and prevent damage to engine components. A basic set of tools will include wrenches, sockets, screwdrivers, and pliers. However, there are also specific tools that are essential for timing-related tasks. A timing light is crucial for checking and adjusting the ignition timing. It allows you to see the timing marks on the crankshaft pulley while the engine is running. A timing belt or chain tensioner tool is necessary for releasing and tensioning the timing belt or chain during replacement.

This tool ensures that the belt or chain is properly tensioned to prevent slipping or premature wear. A harmonic balancer puller is used to remove the harmonic balancer from the crankshaft, which is often necessary for accessing the timing belt or chain. A camshaft locking tool is used to hold the camshafts in place during timing belt or chain replacement, preventing them from rotating and causing misalignment. A crankshaft positioning tool is used to align the crankshaft at top dead center (TDC) before installing the timing belt or chain. A scan tool can be used to read trouble codes related to timing issues and monitor engine parameters. A dial indicator can be used to accurately measure valve lift and timing. Finally, always refer to the vehicle's service manual for specific tool requirements and procedures. Using the right tools for the job can make the process easier, safer, and more accurate. Investing in quality tools is a worthwhile investment for anyone planning to work on engine timing, ensuring that the job is done correctly and preventing potential damage to the engine.

Fun Facts About Engine Timing

Did you know that the concept of engine timing dates back to the earliest days of internal combustion engines? Early engines relied on very basic mechanical systems to control timing, and adjustments were often crude and imprecise. Over time, advancements in technology have led to the sophisticated timing mechanisms found in modern engines. Another fun fact is that some engines use a timing belt made of reinforced rubber, while others use a timing chain made of metal. Timing belts are quieter but require regular replacement, while timing chains are more durable but can stretch over time.

Variable valve timing (VVT) is a technology that allows the camshaft timing to be adjusted on the fly, improving engine performance and fuel efficiency. VVT systems can adjust the timing of the intake and exhaust valves independently, optimizing the combustion process for different driving conditions. Some engines even use cylinder deactivation technology, which shuts off certain cylinders to improve fuel economy at low loads. Engine timing plays a crucial role in cylinder deactivation, ensuring that the valves are closed on the deactivated cylinders to prevent pumping losses. The fastest piston speed in a typical car engine can exceed 50 miles per hour. Precise timing is essential to ensure that the valves open and close at the correct moments, even at these high speeds. Engine timing is not just for gasoline engines; diesel engines also rely on precise timing for efficient combustion. Diesel engines use compression ignition, where the air-fuel mixture is ignited by the heat generated from compression, and timing plays a critical role in controlling the injection of fuel into the cylinders. Exploring these fun facts about engine timing can give you a greater appreciation for the intricate workings of the internal combustion engine. Understanding the history, technology, and trivia behind engine timing can make you a more knowledgeable and engaged car enthusiast.

How To Adjust Engine Timing

Adjusting engine timing can be a complex process that requires precision and attention to detail. The specific procedure will vary depending on the make and model of your vehicle, so it's essential to consult the service manual for detailed instructions. In general, adjusting engine timing involves the following steps. First, locate the timing marks on the crankshaft pulley and the engine block. These marks are used to align the engine at top dead center (TDC) on the compression stroke of the first cylinder.

Next, connect a timing light to the engine. The timing light will strobe when the spark plug fires, allowing you to see the timing marks on the crankshaft pulley. Start the engine and let it warm up to operating temperature. Aim the timing light at the crankshaft pulley and observe the timing marks. The timing mark should align with the specified mark on the engine block. If the timing is off, you'll need to adjust the distributor or reprogram the ECU. For older vehicles with a distributor, loosen the distributor hold-down bolt and rotate the distributor until the timing marks align. Tighten the hold-down bolt and recheck the timing. For newer vehicles with electronic engine management systems, you may need to use a scan tool to adjust the timing. The scan tool will allow you to reprogram the ECU to adjust the ignition timing. After adjusting the timing, recheck the timing with the timing light to ensure that it's within the manufacturer's specifications. Finally, perform a test drive to ensure that the engine is running smoothly and efficiently. If you're not comfortable adjusting engine timing yourself, it's best to seek professional help. A qualified mechanic can accurately adjust the timing and ensure that your engine is running at its optimal performance level. By following these steps and taking the necessary precautions, you can successfully adjust engine timing and improve your vehicle's performance and fuel economy.

What If Engine Timing is Off?

When engine timing is off, the consequences can range from minor inconveniences to major engine damage. The severity of the symptoms will depend on the degree of misalignment and the specific engine design. One of the most common symptoms of misaligned timing is a rough-running engine, especially at idle. The engine may vibrate excessively and feel unstable. Reduced power and poor fuel economy are also common symptoms. The engine may struggle to accelerate and may not be able to reach its full potential.

Increased emissions are another consequence of misaligned timing. The engine may produce more pollutants, leading to a failed emissions test. Unusual noises, such as knocking, pinging, or backfiring, can also indicate a timing problem. These noises are caused by abnormal combustion patterns in the cylinders. In severe cases, misaligned timing can lead to engine damage. The valves may collide with the pistons, causing bent valves, damaged pistons, and other serious problems. If the timing belt or chain breaks, it can also lead to catastrophic engine damage. The valves may slam into the pistons, causing extensive damage to the cylinder head and engine block. If you suspect that your engine timing is off, it's important to address the issue promptly. Ignoring the symptoms can lead to more serious and costly damage. Have your vehicle professionally diagnosed and repaired to ensure that the timing is properly aligned. By addressing timing issues promptly, you can prevent engine damage and ensure that your vehicle runs smoothly and efficiently for years to come. Proper maintenance and timely repairs are essential for keeping your engine in top condition.

Listicle: Top 5 Signs of a Timing Issue

1.Rough Idle: An engine that shakes and sputters when idling is a classic sign of timing problems. The misaligned valves disrupt the smooth combustion process, causing the engine to struggle to maintain a stable idle.

2.Reduced Power: Notice a lack of pep when accelerating? Misaligned timing can significantly reduce engine power, making it difficult to climb hills or merge onto the highway.

3.Poor Fuel Economy: If you're filling up your gas tank more often than usual, misaligned timing could be the culprit. The inefficient combustion process wastes fuel, leading to decreased mileage.

4.Unusual Noises: Knocking, pinging, or backfiring sounds from your engine are warning signs of timing issues. These noises indicate abnormal combustion patterns that can damage engine components.

5.Check Engine Light: The check engine light is your car's way of telling you something is wrong. A timing-related issue will often trigger the check engine light, prompting you to investigate further.

Ignoring these signs can lead to more serious engine damage and costly repairs. If you notice any of these symptoms, it's crucial to have your vehicle professionally diagnosed and repaired. Proper maintenance and timely repairs are essential for keeping your engine running smoothly and efficiently.

Question and Answer Section

Q: What is the difference between a timing belt and a timing chain?

A: A timing belt is made of reinforced rubber, while a timing chain is made of metal. Timing belts are quieter but require regular replacement, while timing chains are more durable but can stretch over time.

Q: How often should I replace my timing belt?

A: Consult your vehicle's service manual for the manufacturer's recommended replacement interval. Typically, timing belts should be replaced every 60,000 to 100,000 miles.

Q: Can I adjust engine timing myself?

A: Adjusting engine timing can be a complex process that requires precision and attention to detail. If you're not comfortable working on engines, it's best to seek professional help.

Q: What happens if my timing belt breaks?

A: If your timing belt breaks, it can lead to catastrophic engine damage. The valves may collide with the pistons, causing bent valves, damaged pistons, and other serious problems.

Conclusion of Engine Timing Explained: Importance and How It Works

Understanding engine timing is crucial for maintaining the health and performance of your vehicle. From the precise choreography of valves and pistons to the critical role of timing belts and chains, every aspect of engine timing contributes to efficient combustion and optimal engine operation. By recognizing the signs of a timing issue, following recommended maintenance schedules, and seeking professional help when needed, you can ensure that your engine runs smoothly, efficiently, and reliably for years to come. Whether you're a seasoned mechanic or a casual car enthusiast, a solid grasp of engine timing will empower you to make informed decisions about your vehicle's care and maintenance.